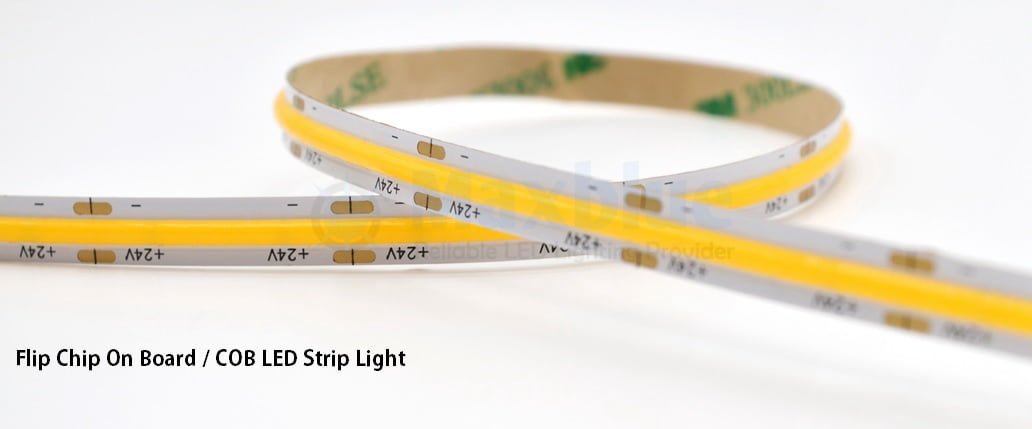

The lighting designer always dreams a kind of led strip without dots and spots, since this flixble and linear continous lighting can be used various places.

With the cob technology improvement, the flip chip on board can be used on the fpcb now. This blog will show you how to make the flip chip on board/cob led strip lighting by Maxblue Lighting.

1. Coated with solder paste on the flexible PCB.

2. Set the Die Bond program and make sure the chips are bounded on the fpcb tightly.

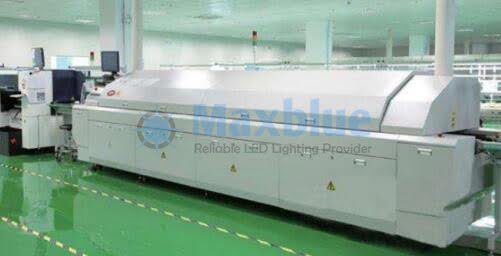

3. Reflow soldering to dry the solder past points.

4. Mix silica gel and phosphor to get the required color temperature.

5. Phosphor dispensing coating and jetting process.

6. Bake the fpcb in the oven.

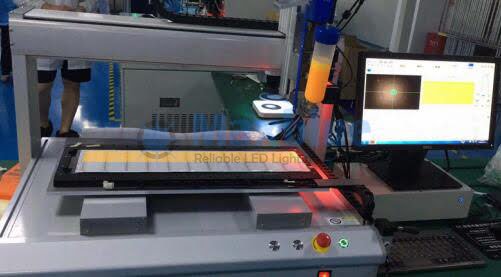

7. Test the COB led strip if it is qualified.

8. Connect the 0.5meter to 5-10meter per reel.