Mastering Epoxy Curing with UV LED Strip Lights: A Comprehensive Guide

Introduction

Epoxy resin has surged in popularity for its versatility and ability to turn creative visions into tangible reality. From DIY epoxy art enthusiasts to professional artisans, epoxy is celebrated for its strength, durability, and its capacity to encapsulate everything from intricate jewelry to massive tabletops. But the true alchemy of epoxy lies in its curing process, and when it comes to efficiency and precision, UV LED strip lights for epoxy curing are the secret ingredient.

In this comprehensive guide, we will illuminate the path to mastering epoxy curing with UV LED strip lights. Whether you’re an experienced epoxy enthusiast or just starting your journey, this guide will empower you with the knowledge and techniques to achieve flawless epoxy curing results.

Chapter 1: Understanding Epoxy Curing

To master epoxy curing with UV LED epoxy curing strip lights, it’s essential to grasp the fundamentals of epoxy curing. This chapter covers:

The Chemistry of Curing: Explore the chemical reactions that occur during UV epoxy curing and how UV light influences epoxy curing.

Types of Epoxy: Learn about the various epoxy formulations and their suitability for UV epoxy curing.

Curing Agents: Understand the role of curing agents in epoxy UV curing and how to choose the right one for your project.

Chapter 2: The Power of UV LED Strip Lights

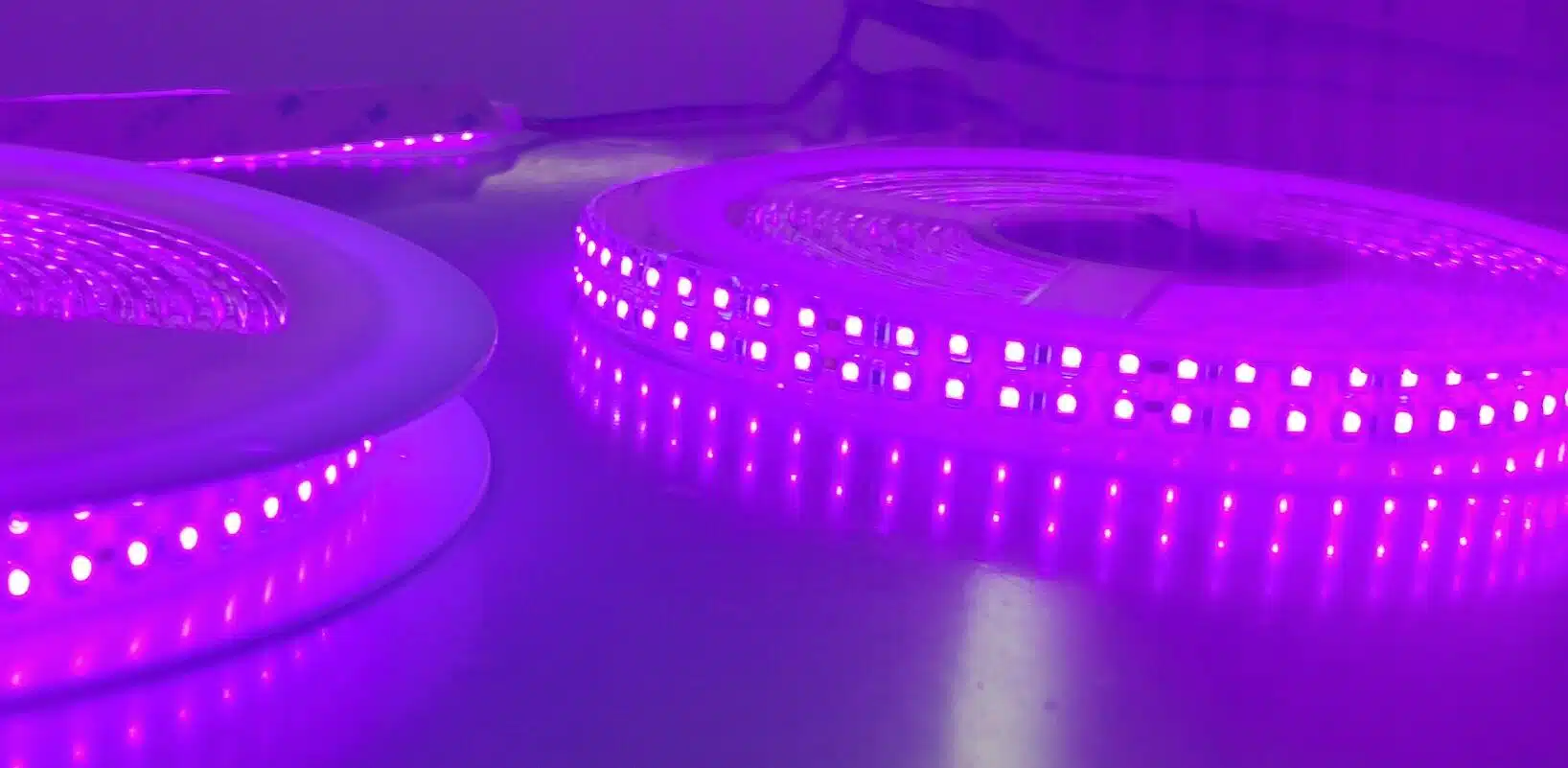

Discover why UV LED strip lights have become the preferred choice for epoxy curing:

Benefits of UV LEDs: Explore the advantages of UV LED strip lights for epoxy curing over traditional curing methods.

Case Study 1: UV LED Strip Lights in Transparent Tubing Imagine you’re working on a project that involves encapsulating delicate items like flowers or seashells in epoxy for preservation. To ensure the epoxy cures evenly and without disturbing the objects, you can use UV LED strip lights placed inside transparent tubing. This setup creates a controlled curing environment, allowing the epoxy to cure uniformly while keeping your precious items intact.

Wavelengths and Photo initiators: Understand the importance of the UV light spectrum and how it interacts with epoxy during UV curing.

Case Study 2: Tailored Photo Initiators for Specific Projects One of the fascinating aspects of UV epoxy curing is its adaptability. Suppose you’re working on a project that requires different curing times or levels of transparency. In that case, you can experiment with various photo initiators and UV LED strip lights that emit specific wavelengths to achieve the desired results. This versatility allows you to fine-tune your epoxy curing process for each project’s unique requirements.

Choosing the Right UV LED Strip: Learn how to select the appropriate UV LED strip for epoxy curing needs.

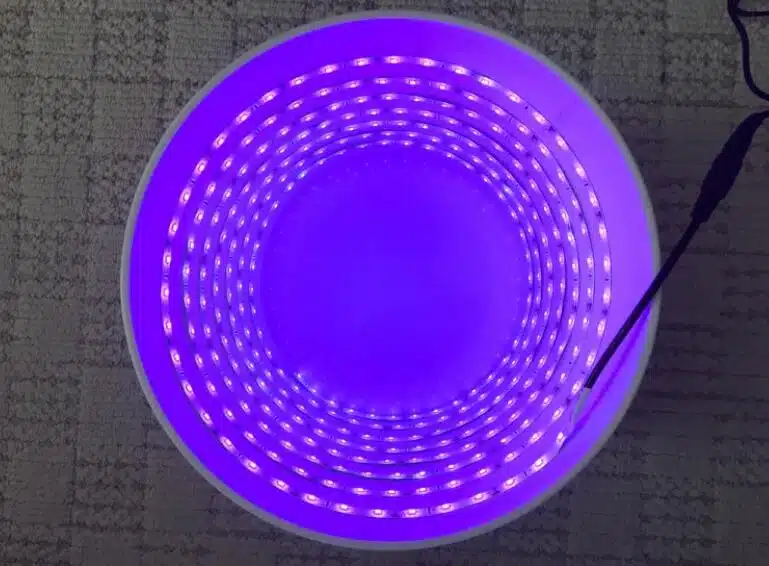

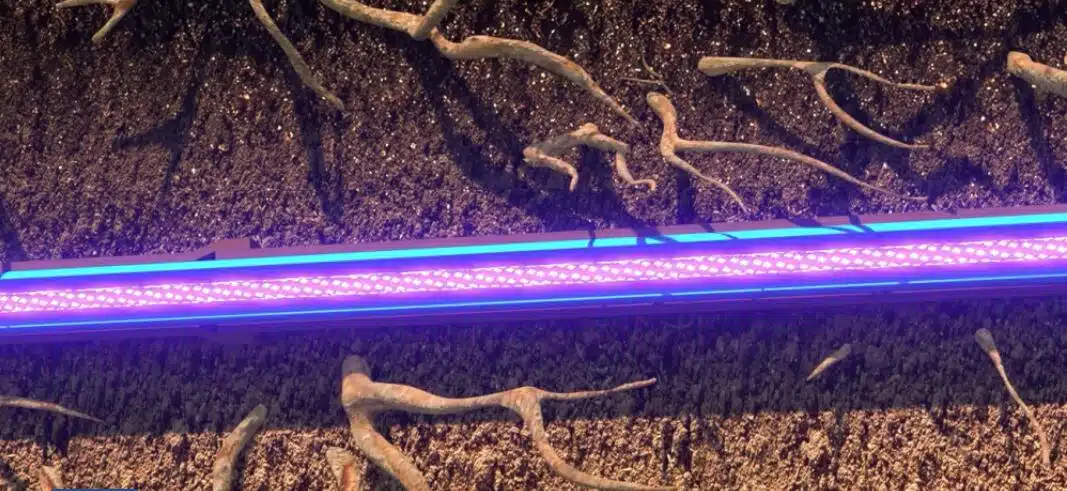

Case Study 3: Epoxy Curing for Pipe Relining In the world of plumbing and infrastructure, repairing damaged pipes often involves pipe relining, where a new pipe is created within the existing one. UV LED strip lights play a pivotal role in this process. Contractors can wrap the UV light strip around a soft cylinder, creating a flexible, mobile curing unit. As this light train traverses the inside of the pipe, the epoxy resin cures rapidly, forming a durable inner lining. This method reduces the need for extensive excavation and streamlines pipe rehabilitation.

Chapter 3: Preparing for Epoxy Curing

Prepare your workspace and materials for a successful epoxy UV curing process:

Workspace Setup: Tips for creating a clean and organized epoxy workspace for UV resin curing.

Safety Measures: Essential precautions to protect yourself when working with UV light-curing epoxy.

Mixing Epoxy: Proper epoxy mixing techniques to ensure a uniform curing process during UV epoxy curing.

Chapter 4: Curing Techniques with UV LED Strip Lights

Delve into the techniques that will elevate your UV epoxy curing:

Proper Application: Learn how to apply epoxy evenly for consistent results during UV epoxy curing.

Case Study 4: Evenly Coating Large Surfaces When working on sizable projects like coating tabletops or counter tops, achieving an even epoxy application can be challenging. To overcome this, professionals use UV LED strip lights strategically positioned above the surface. The even distribution of UV light ensures uniform curing, eliminating the need for extensive sanding or rework.

Positioning UV LED Strips: The art of positioning UV LED strips for epoxy curing for optimal curing coverage.

Case Study 5: Creating Custom Jewelry with UV LED Strips Jewelry makers often employ UV LED strip lights to cure epoxy when creating custom pieces. To achieve intricate designs, they carefully position UV LED strips around jewelry molds, ensuring that every detail is exposed to the curing light. This precision results in flawless jewelry, showcasing the potential of UV LED strip lights in fine craftsmanship.

Monitoring and Timing: Strategies for monitoring the curing process and managing curing times during UV light epoxy curing.

Case Study 6: Crafting Art with Controlled Timing Artists who work with epoxy to create mesmerizing resin art pieces often require precise control over curing times. By using a timer and monitoring the curing process under UV LED strip lights, they can intervene at just the right moment. This level of control enables artists to achieve stunning effects, such as 3D layers and captivating color blends.By integrating these case studies, we can see how UV LED strip lights are versatile tools that empower creators and professionals in various fields to achieve remarkable results in epoxy curing. These real-world examples highlight the immense potential and flexibility of UV LED strip lights in the epoxy curing process.

Chapter 5: Troubleshooting and Tips

Anticipate common challenges and discover expert tips for epoxy curing success:

Troubleshooting: How to address common curing issues like air bubbles and uneven curing during UV epoxy curing.

Finishing Touches: Post-curing steps to enhance the aesthetics and durability of your epoxy projects for UV curing epoxy resin.

Advanced Techniques: Explore advanced techniques and creative possibilities for epoxy curing using UV LED strip lights.

Conclusion: Becoming an Epoxy Curing Maestro

As you wrap up this comprehensive guide, you’ll have acquired the knowledge, skills, and confidence to master epoxy curing with UV LED strip lights. Whether you’re creating art, enhancing your home decor, or pursuing professional projects, the fusion of epoxy and UV LEDs for epoxy curing unlocks a world of possibilities. With each project, you’ll continue to refine your craft and create stunning, durable epoxy masterpieces that showcase your mastery of this transformative process.

Epoxy curing with UV LED strip lights is an art form that blends science, precision, and creativity. It’s a journey of continuous learning and discovery, and you’re now equipped with the tools to embark on it with confidence. Welcome to the radiant world of epoxy curing mastery using UV LED strip lights!

评论